FRP Pipe/FRP Tank/Filament Winding Machine/Electrolytic Cell/FRP Grating Machine/FRP Pultrusion Machine

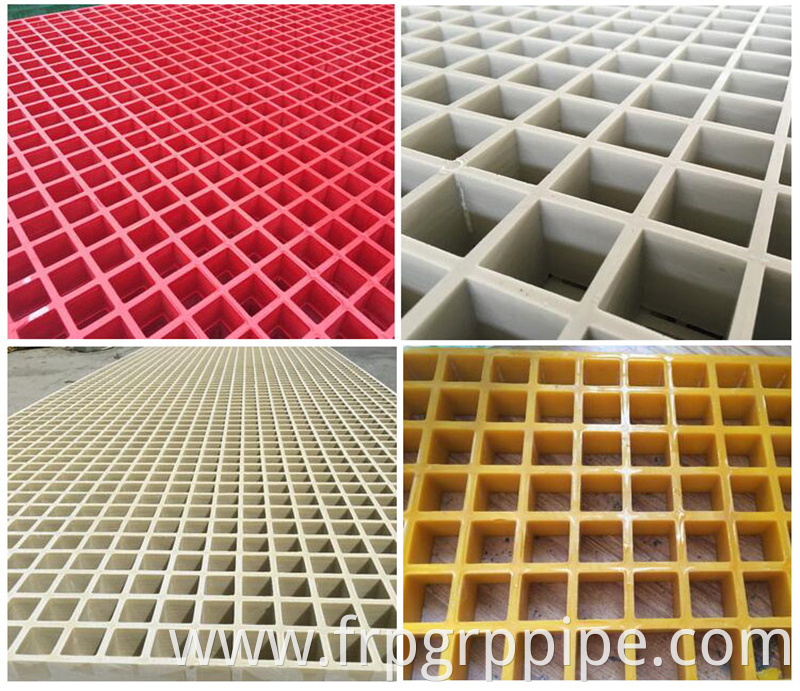

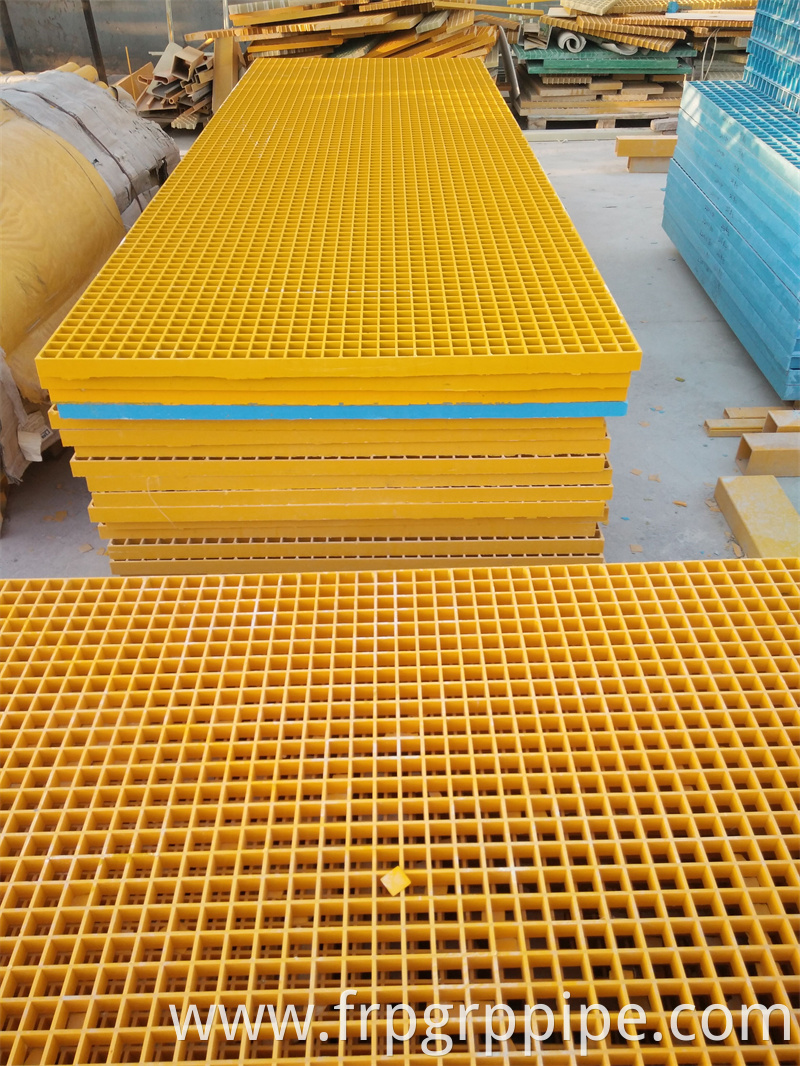

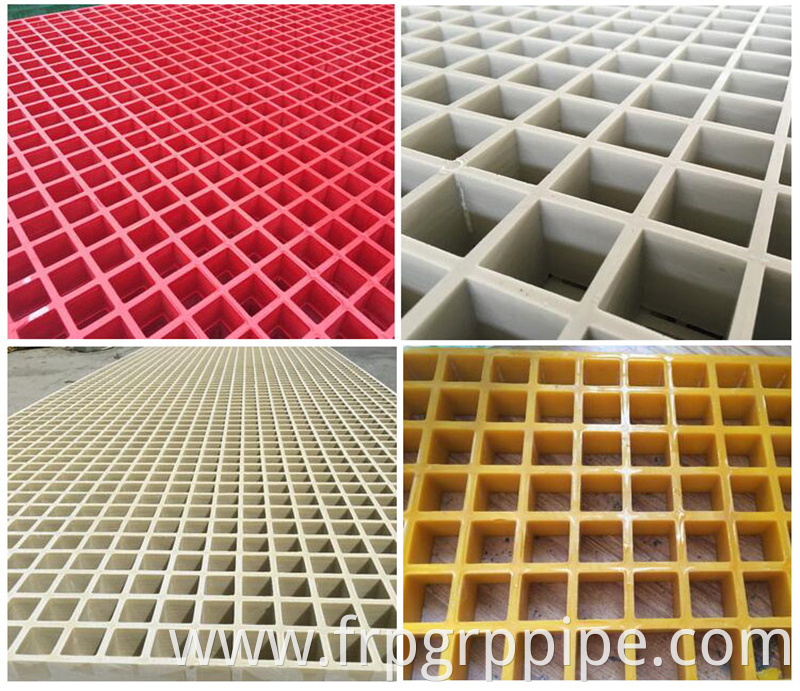

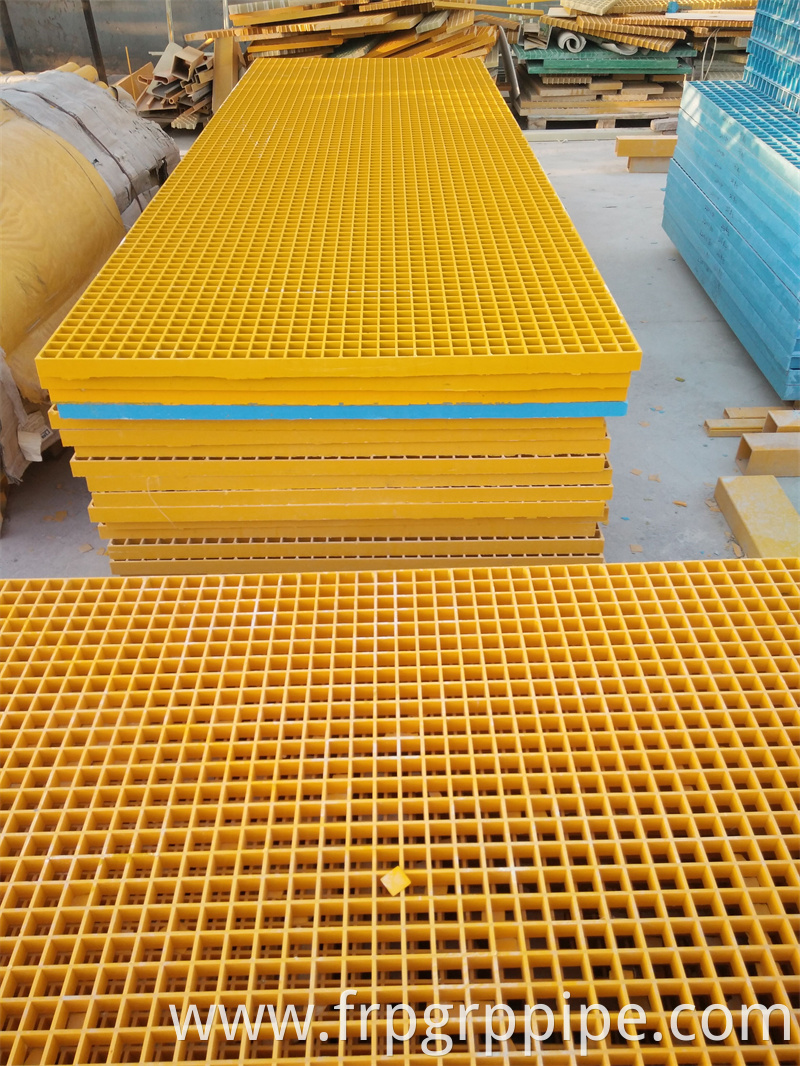

For GRP Grating, unsaturated resin (include: Isophthalic, Orthophthalic, Vinyl ester, Phenolic, Bisphenol-A,etc) as it's matrix, and glassfiber roving (winding or pultrusion, C-glass or E-glass) as it's reinforced material. FRP Grating can be made on metal mould, also can be made by hand lay-up, then form a whole under heating, it's appearance is smooth, beautiful, and good inner quality, the content of fiberglass is over 30% (by weight). It has light weight, high strength, anti-corrosive, fire retardant, firm & anti-slippy, insulation, anti-impact, easy cutting, long service life, and be free of maintenance, etc characteristics. It is widely used as operation platform, equipment platform, manway, stair treads, trench cover, handrail, goods shelves, filter plate, support of packing in petroleum, chemical, power station, plating, pulp-making, brewing, pharmacy, metallurgy, food processing, transportation, dyeing, waste water treatment, etc industries.

- Firm bond between fiberglass roving interlaced layer and resin: fiberglass roving be infused fully by resin, to make grating has anti-corrosion furthest.

- Whole structure distributes the load to longitudinal and transverse direction: fiberglass and resin be combined in cross, the whole structure shall distribute the load evenly.

- Anti-corrosion & anti-slippy surface layer: the concave to make the grating has anti-slippy property, it has better anti-slippy if the grating has gritted surface.

- The smooth surface makes the grating has self-cleaning.