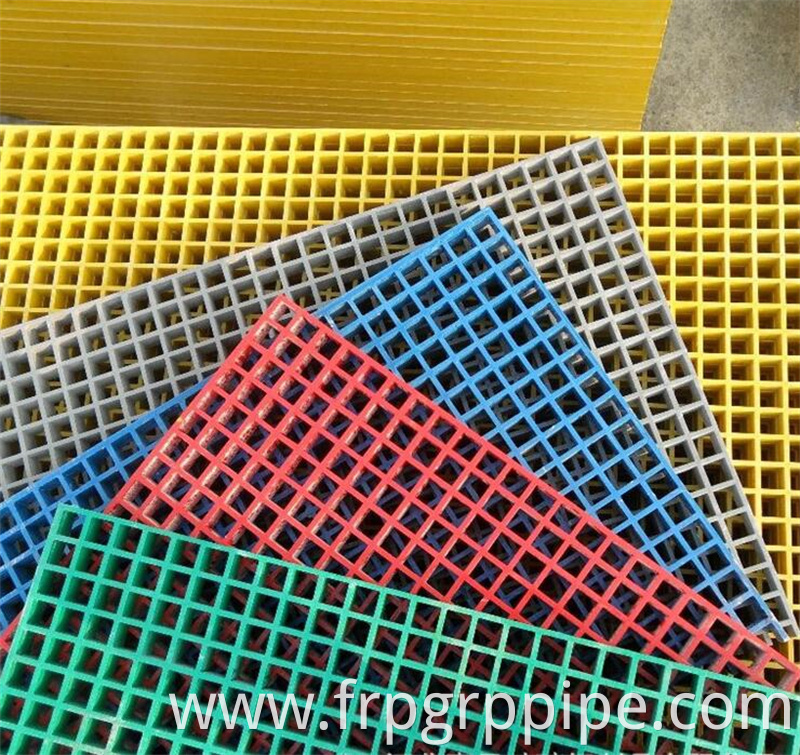

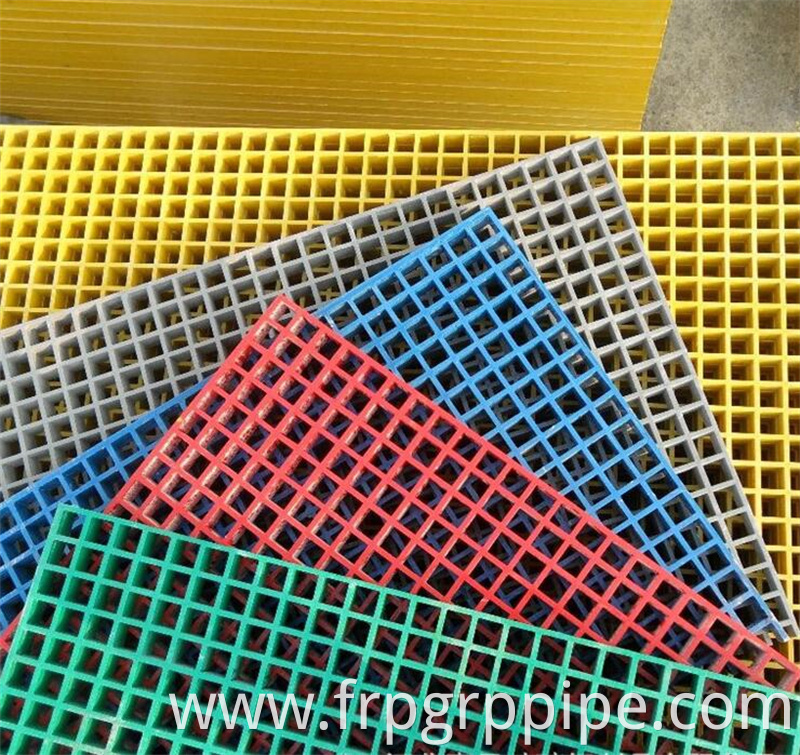

1. FRP Molded Grating Introduction

Molded fiberglass reinforced plastic (FRP) grating provides corrosion resistance in the most demanding environments. Manufactured by combining thermosetting resin with continuous fiberglass rovings in precision molds, each panel contains approximately 65% resin and 35% fiberglass rovings. This combination optimizes corrosion resistance, UV protection, and structural integrity.

Fiberglass Grating is a lightweight and sound alternative to Steel or Aluminum Gratings. Corrosion-resistant and fire-retardant, this product line is ideal for use outdoors or in corrosive environments.

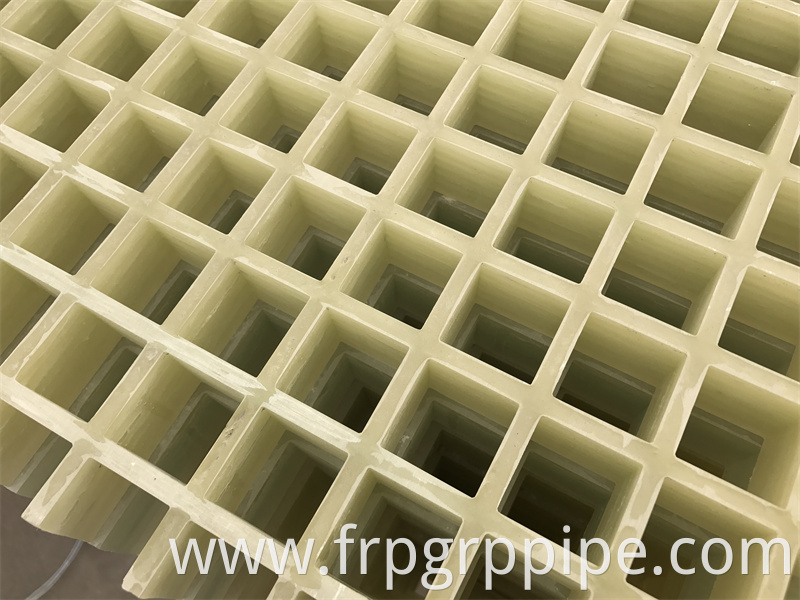

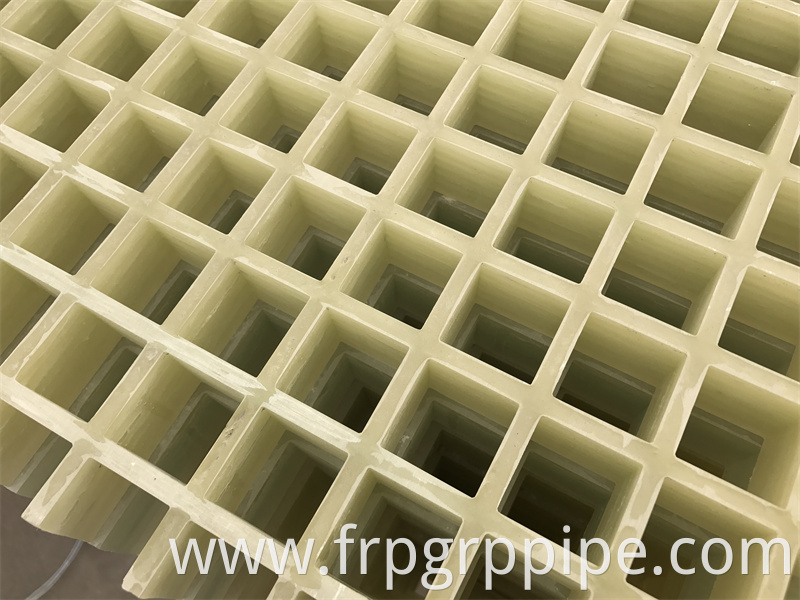

Besides traditional quare mesh type, we also produce rectangulae mesh and micro mesh.

2. Benifits of FRP Molded Grating: > Bi-directional strength - Most cutouts require no additional supportExtended Service Life > Fire Retardant - ASTM E84, Class 1, F.S. 25 or less > High Impact Resistance > Highest level of corrosion resistance > Low Maintenance 3. FRP Molded Grating Surface Type: > Pattern plate > Concave Surface (meniscus profile) - This is how the grating comes naturally out of the mold. The raised edges form a lip which offers slip resistance. > Grit Surface - Excellent slip resistant surface > Smooth Surface - Great for Wastewater Treatment plants or Architectural applications

For GRP Grating, unsaturated resin (include: Isophthalic, Orthophthalic, Vinyl ester, Phenolic, Bisphenol-A,etc) as it's matrix, and glassfiber roving (winding or pultrusion, C-glass or E-glass) as it's reinforced material. FRP Grating can be made on metal mould, also can be made by hand lay-up, then form a whole under heating, it's appearance is smooth, beautiful, and good inner quality, the content of fiberglass is over 30% (by weight). It has light weight, high strength, anti-corrosive, fire retardant, firm & anti-slippy, insulation, anti-impact, easy cutting, long service life, and be free of maintenance, etc characteristics. It is widely used as operation platform, equipment platform, manway, stair treads, trench cover, handrail, goods shelves, filter plate, support of packing in petroleum, chemical, power station, plating, pulp-making, brewing, pharmacy, metallurgy, food processing, transportation, dyeing, waste water treatment, etc industries.

- Firm bond between fiberglass roving interlaced layer and resin: fiberglass roving be infused fully by resin, to make grating has anti-corrosion furthest.

- Whole structure distributes the load to longitudinal and transverse direction: fiberglass and resin be combined in cross, the whole structure shall distribute the load evenly.

- Anti-corrosion & anti-slippy surface layer: the concave to make the grating has anti-slippy property, it has better anti-slippy if the grating has gritted surface.

- The smooth surface makes the grating has self-cleaning.